WE COLLECT CHALLENGES TOGETHER WITH OUR CUSTOMERS TO WIN THEM TOGETHER

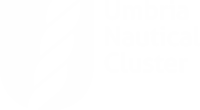

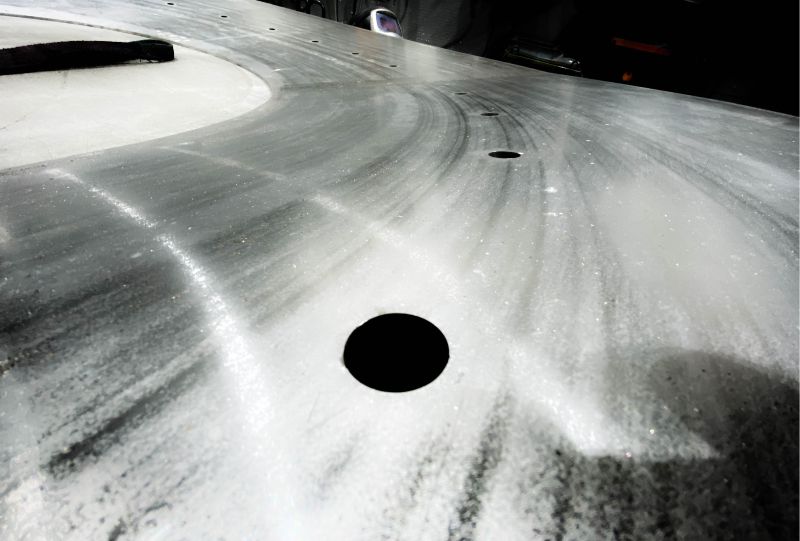

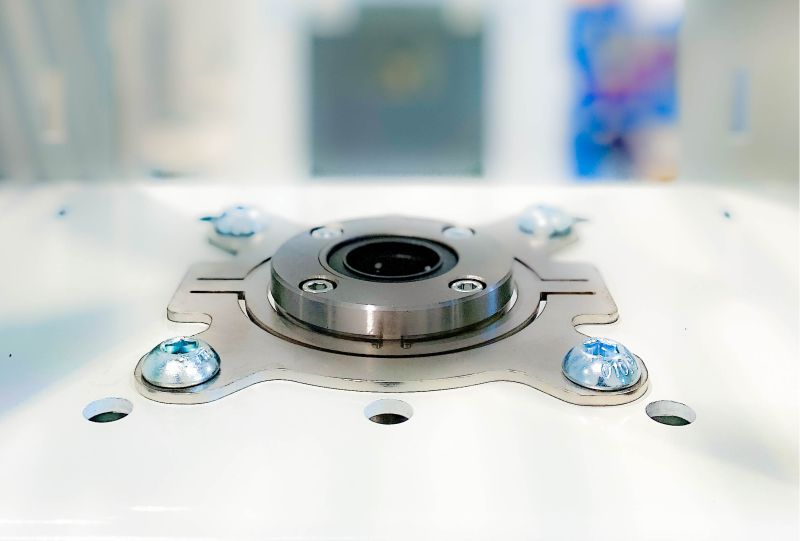

The company choices based on the guiding thread of the continuous improvement of its quality and operational standards for the benefit and full satisfaction of all our customers, allow us to maintain full competitiveness also in the aeronautical sector, offering milling services by means of pantograph, plasma cutting, waterjet cutting, laser cutting, bending, welding.

CERTIFIED COMPANY

Mazzocchi Srl has been certified EN-UNI-ISO9001 for many years and has made compliance with the standard its strong point, this in the total vision of the needs of its customers. The company is qualified for various welding processes MIG / MAG, TIG, ELECTRODE, SUBMERSIBLE ARC according to ASME_SEC_IX_2013

PLANT CONSTRUCTION FOR CND: LP – RX – MX

Mazzocchi Srl designs and manufactures systems for non-destructive testing also in collaboration with leading companies in the sector. In particular, the activity focuses on the construction of: Penetrating liquid control systems – control cabins – washing cabins – bunker for x-ray controls.

DESIGN

Our specialized team follows the production at all stages: from the analysis and development of the request to the production and delivery of the final product. A dedicated team supports the customer in all his requests, and coordinates all the production phases for the definitive development of the product.

OUR BUILDINGS

Mazzocchi srl operates on two 8000sqm buildings for the production, processing and handling of goods. Possibility of world wide shipments, and production timing is the strong point of precise and punctual productivity. All our employees are highly qualified with subsequent targeted and organized refresher courses.

ENVIRONMENT

Mazzocchi Srl in addition to self-producing a third of the energy consumed through a photovoltaic system, we purchase electricity from certified renewable sources. Mazzocchi operates in strict compliance with the regulations regarding waste disposal.

OUR WORKSHOP AND THE TEAM

Mazzocchi srl operates in 4000sqm covered and 2000sqm outside. Possibility of world wide shipments, and production timing is the strong point of precise and punctual productivity. All our employees are highly qualified with subsequent targeted and organized refresher courses.